Design preparation: Customer provide original logo in vector file.

Film preparation: We make the logo into ribbon design, separating colors from design,

Studio make film, one film one color.

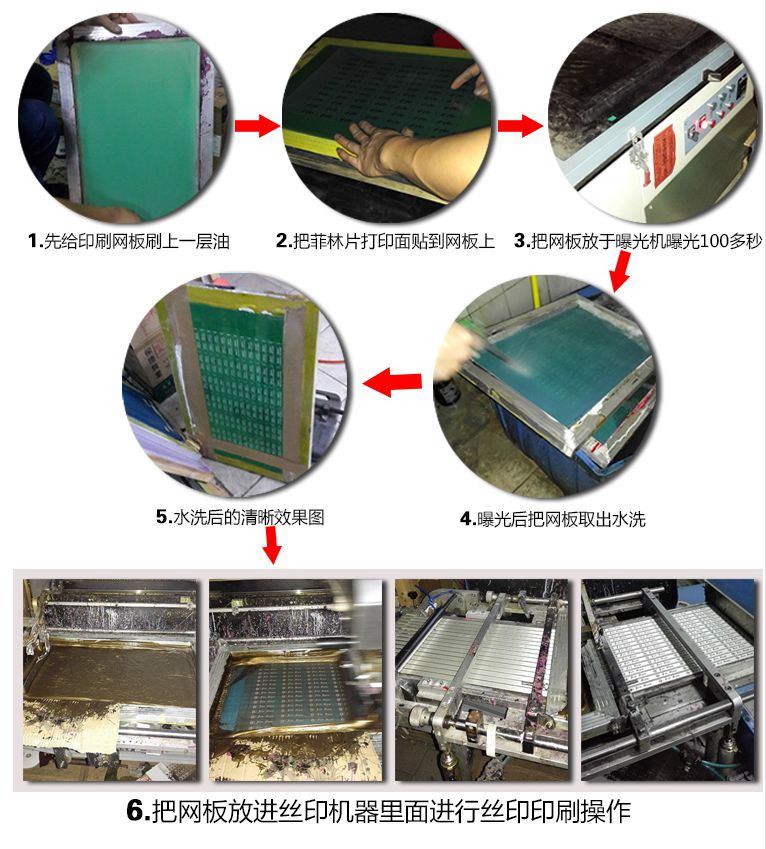

Mold making: Apply a layer of photosensitive adhesive to the printing screen and dry it, put film onto the screen after drying and expose it. Rinse the screen with water after exposure, then we get a screen mold with the color picture we want.Design preparation: Customer provide original logo in vector file.

Film preparation: We make the logo into ribbon design, separating colors from design,

Studio make film, one film one color.

Mold making: Apply a layer of photosensitive adhesive to the printing screen and dry it, put film onto the screen after drying and expose it. Rinse the screen with water after exposure, then we get a screen mold with the color picture we want.

Ink preparation: According to the design color requirements, prepare printing inks modulation by different mixing.

Ribbon preparation: Lay the ribbon on work platform, put the screen mold on ribbon,

Printing: Apply the ink on the screen plate, and then use a scraper to scrape the ink flat so that the ink can be penetrated and printed on the ribbon through the screen.

Drying the ribbon: dry and solidify the printed ribbon to make the ink firmly adhere to the ribbon.

Inspection and Packaging: Check the printing effect, then package to rolls.

These are the main steps of general ribbon screen printing. The specific process may vary according to different printing equipment and actual conditions.